Introduction

The digital transformation of technologies and services provides the basis of the Industry 5.0, which complements the existing Industry 4.0 paradigm by highlighting research and innovation as drivers for a transition to a sustainable, human-centric and resilient industry.

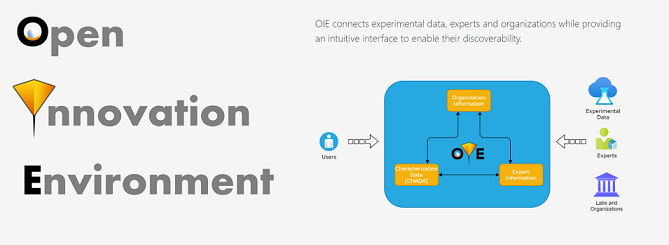

The materials and manufacturing industry is becoming more and more reliant upon a digital ecosystem in which stakeholders are connected, comprising aspects such as data and knowledge, technologies, human resources, applications, and operations. Digital market-places are being built that connect manufacturers, suppliers, distributors, and their consumers so that they can share resources to create what are essentially virtual organisations. Today, digital industry ecosystems are evolving rapidly, driven by powerful economic forces, and they will have a lasting impact on how manufacturers interact with materials suppliers and their customers.

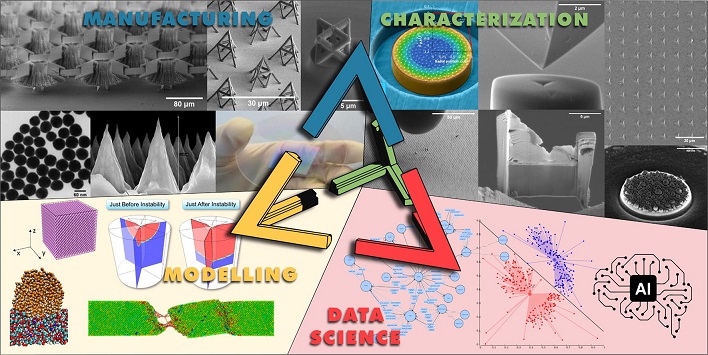

Materials discovery and life cycle management requires the involvement of skills and capabilities from many disparate communities ranging from chemistry, materials science, physics, engineering, information technologies and data science. Key advanced technologies and tools from these fields include materials synthesis, robotics, characterisation and modelling, ML/AI and ontologies. A Common Digital Ecosystem needs to warrant interoperability between all such “horizontal enabler” technologies and to capitalise on commonalities between them. Their integration will be a cornerstone in the digital transformation of the manufacturing industry.

Improving resilience and sustainability as well as ensuring safety of materials in all products throughout the life cycle requires a wide and complex range of trusted information on materials and process behaviour, along the entire lifecycle of the product and its associated material, reaching far beyond the quality and quantity of data sets currently available to industry.

Recent advances in “horizontal enabler” technologies including materials simulation, characterisation and materials informatics demonstrates that digital integration would enable closed-loop research that can design, perform and interpret simulations and experiments in an ecosystem of companies collaborating cross-borders.

In this short communication, we address the challenge to go beyond the ordinary multidisciplinary research approach. We envisage a common, digitally integrated materials ecosystem incorporating ontologies for different materials technologies and domains providing full interoperability. Such a system will enable companies to collaborate on more intelligent materials analysis, use and re-use of data, supported by advanced data science tools (including machine learning and artificial intelligence).

Such an industrial ecosystem will support materials and product manufacturing companies, in meeting their strategic objectives regarding resilience and sustainability, leading to more targeted design and development of safe and sustainable materials and processes, faster upscaling and effective quality control.

The European Materials Modelling and Characterisation Councils (EMMC[1] and EMCC[2]) are associations with a broad network of industrial stakeholders, focussing on horizontal enablers and who together address the cross-domain issues that arise during the ongoing digital industrial revolution and with this document we put forward our views for the future.

The document further informs on

- State of the Art of Materials Development Integration

- Drivers to digitally transform the Materials Ecosystem

- Activities proposed to create and support a Materials Ecosystem

- Expected Benefits of a Materials Ecosystem

Read more…